Welcome to Rongda Machinery Co., Ltd

Toggle Navigation

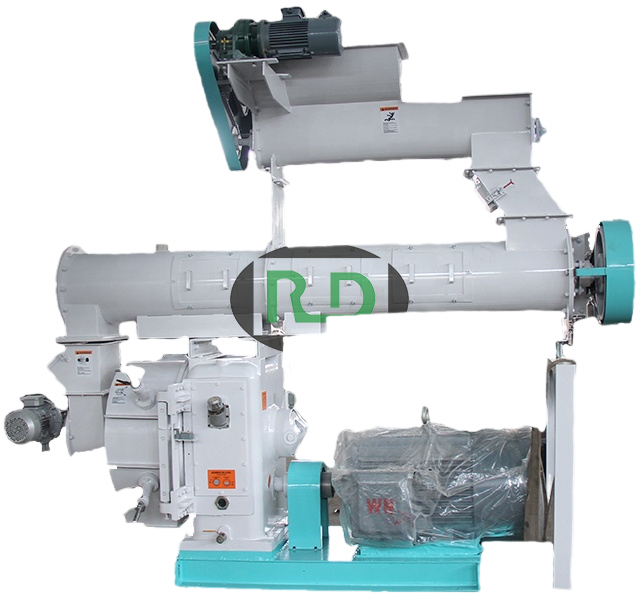

The biomass pellet machine plays a vital role in the production process and is considered as the core equipment of a biomass pellet fuel plant. Therefore, the proper usage and maintenance of the biomass pellet machine are crucial for enhancing production efficiency, continuous production, and improving machine stability. The following are some essential points to note in the operation:

The biomass pellet machine plays a vital role in the production process and is considered as the core equipment of a biomass pellet fuel plant. Therefore, the proper usage and maintenance of the biomass pellet machine are crucial for enhancing production efficiency, continuous production, and improving machine stability. The following are some essential points to note in the operation:

1. Regular Lubrication: Regularly lubricate the transmission parts of the biomass pellet machine to ensure its flexible rotation, reduce the workload, and extend its lifespan. Lubricate the main shaft front bearings every 4 hours and the press roller bearings every 2 hours.

2. Changing Gearbox Lubricating Oil: Regularly change the lubricating oil in the gearbox to extend the gear's lifespan.

3. Regular Inspection and Cleaning: Weekly inspection of loose connections and cleaning the feed auger and conditioner to avoid mechanical failure.

4. Check Transmission Keys and Reinforced Flanges: Check the wear and tear of transmission keys and reinforced flanges every half month, and replace them timely to avoid affecting production.

5. Use of High-Quality Pellet Die and Press Roller: Use high-quality pellet die and press roller, and select the compression ratio of the die according to different formulas to ensure smooth discharge and avoid increasing power consumption and reducing production capacity.

6. Adjustment of Pellet Die and Press Roller Clearance: Adjust the pellet die and press roller clearance every shift to ensure smooth operation.

7. Avoiding Overload Production: Production should not exceed the biomass pellet machine’s capacity to prevent accelerated component wear, motor damage, and shorten the machine's lifespan.

8. Efficient Removal of Impurities from Raw Materials: Thorough iron removal and impurity cleaning of raw materials to avoid the entry of foreign objects into the workshop, which could cause machine vibration or die cracking.

Proper operation and maintenance are crucial for extending the lifespan of the biomass pellet machine. Strengthening equipment management and maintenance will significantly improve the company's efficiency.